What is biofilm?

You may think your surface is clean, but there could be an invisible group of pathogens lingering — a biofilm.

Biofilms are all around us. The plaque on your teeth and pink slime in bathrooms are examples of biofilm. Anywhere there is frequent moisture, there is the chance for biofilm to form.

These slimy clusters of pathogens can easily spread, are notoriously hard to kill, and can be harmful. So how do you get rid of it? We'll explain a proven three-step process to kill biofilm, but first let's take a closer at how exactly biofilms form.

What is biofilm?

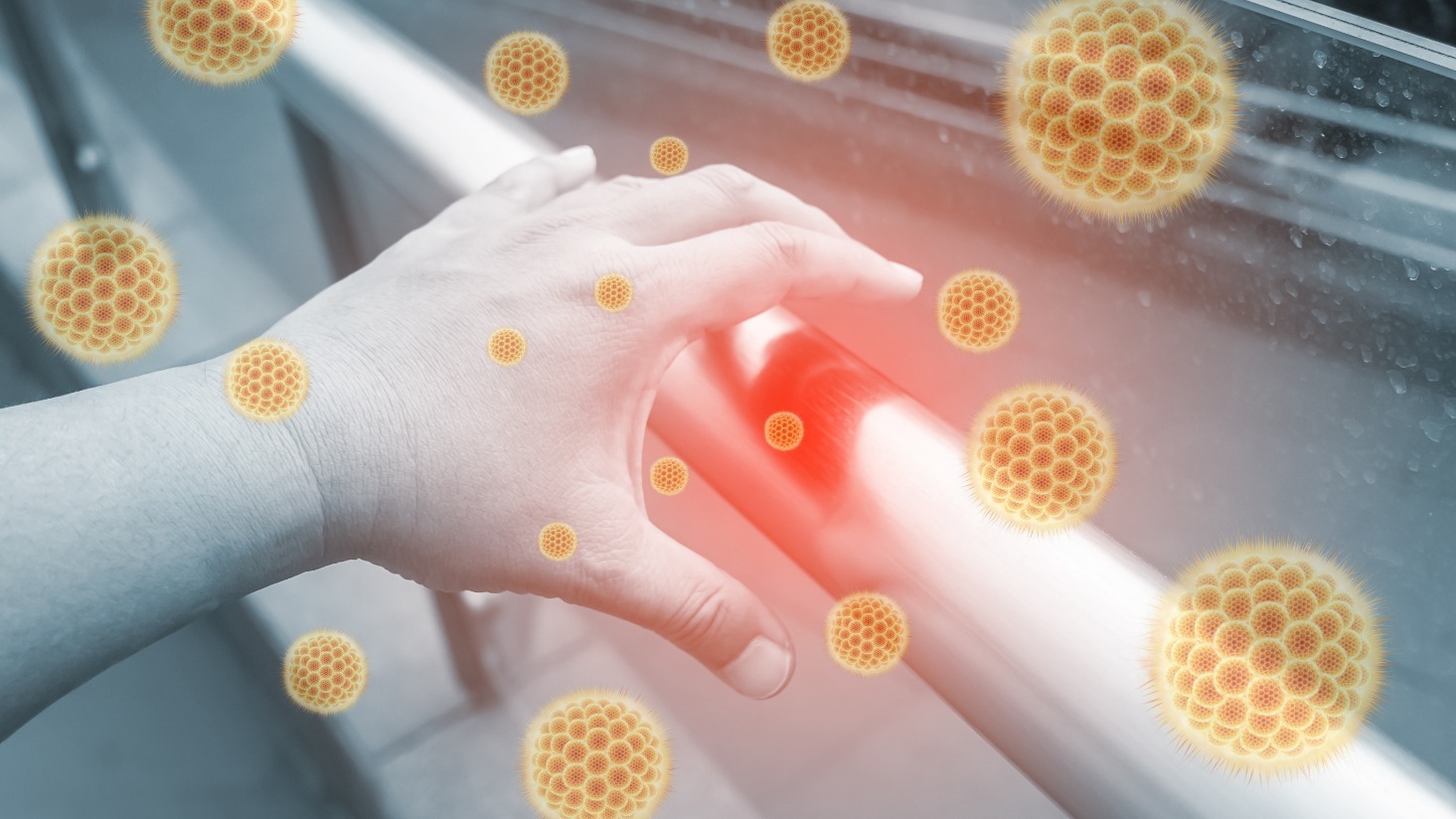

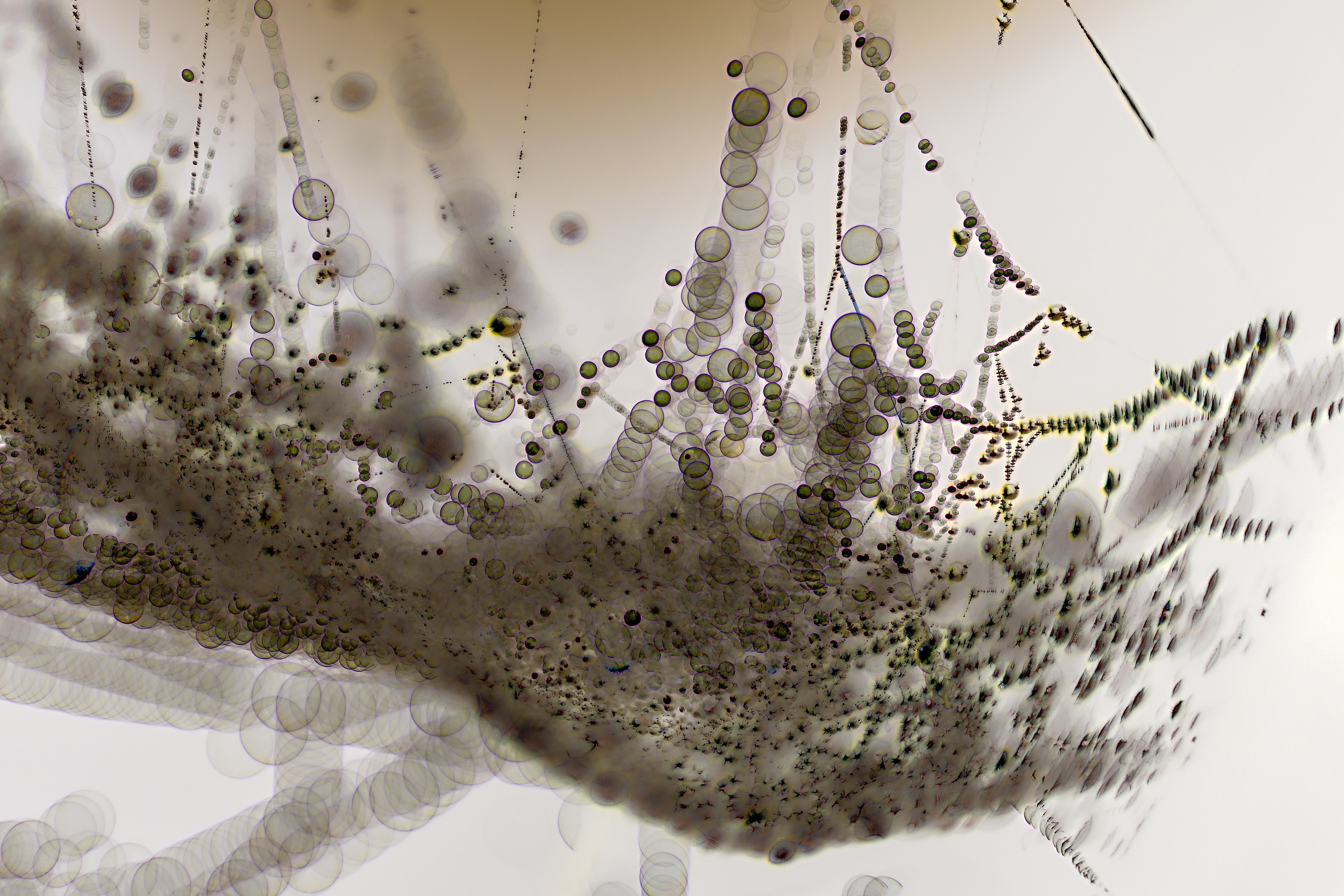

A biofilm is a slimy, glue-like film of bacteria that sticks to a surface and can be incredibly resistant to some cleaning methods and products. Biofilm often forms in a moist environment.

Even though a single type of bacteria can form a biofilm, they often contain many types of bacteria, viruses including SARS-CoV-2 (the virus that causes COVID-19), fungi, algae, yeasts, protozoa, debris, and more.

You can think of a biofilm as a small cluster or city of pathogens. They are all grouped together and protected within the film that keeps them moist and growing.

Similar to cities, parts of the biofilm can break off and create a new colony, easily spreading across surfaces. This also increases the chance to spread illness.

Biofilms can spread relatively quickly since pathogens replicate every 21 minutes.

Biofilms can often be harmful and can be the source of disease outbreaks. It's especially important to keep medical equipment free from biofilm.

The Center for Biofilm Engineering at Montana State University has an entire team dedicated to studying biofilm. They say biofilms found urinary catheters are responsible for 13,000 deaths across the country every year. Biofilms can also be the source of chronic wounds that never heal, leading to amputations.

How to get rid of biofilm

The best way to get rid of biofilm is through a three-step process of cleaning, disinfecting, and protecting.

Because the clusters of bacteria and other pathogens are wrapped in a protective layer, just spraying and rinsing isn't going to get rid of them.

Biofilm must be agitated and broken apart before they can be removed. If you're using only antimicrobial products, it's important to note that they can't penetrate the biofilm, so bacteria will stay on the surface.

Here is an example of a three-step process to get rid of biofilm using products that we sell in our online store.

1. Cleaning

The first step is to scrub and agitate the surface with a cleaner, like the multi-task cleaner below by ZBioScience. The company developed cleaning products that use probiotics and enzymes to get rid of harmful pathogens. ZBioScience products are safe enough to use on any surface, including food preparation areas.

The cleaner is considered a GRAS (generally recognized as safe) substance by the Food and Drug Administration. It's proven effective against salmonella, staph, and other pathogens.

2. Disinfecting

If you're using ZBioScience products, you can skip disinfecting unless it is required by your facility. The multi-task cleaner and enviro-mist protectant by ZBioScience continue to work against biofilm and other harmful pathogens on surfaces for days after being applied.

But if your facility requires disinfection, you should apply it only after you've agitated the surface (and biofilm) by cleaning it. By definition, a disinfectant is a chemical product that claims to kill pathogens after a surface is cleaned.

To be marketed as a disinfectant, the product must be registered with the EPA. Disinfectants may be required in some buildings, like schools.

Vital Oxide is an EPA-registered hospital disinfectant that has the EPA's lowest toxicity rating. While it's strong enough to use in hospitals, it can also be diluted for use in other commercial buildings.

Vital Oxide is uniquely safe and able to be used in diverse environments including soft surfaces and food prep areas without rinsing.

It can be applied the same way you applied the cleaner or with a Fogger like this one:

3. Protecting

Protecting is the last step in the process, but probably the most important. A surface protectant can keep working in areas between weekly or scheduled cleanings.

ZBioScience makes a protectant called Enviro Mist. The probiotics and enzymes in the product replace bad bacteria with good bacteria to stop pathogens from spreading.

This product can be applied with a fogger or an electrostatic sprayer.

For information on the science behind cleaning, disinfecting, and protecting, read this article.

How to tell if biofilm is destroyed

There is no absolute way to tell if biofilms are completely gone. There is, however, a test that can give you a clear understanding of how bacteria on a surface are reduced.

The test looks at the amount of ATP (adenosine triphosphate) on a surface. ATP is found in almost all cells, including bacteria. The lower the reading of ATP, the cleaner the surface. A clean surface is less likely to harbor biofilm and pathogens.

For example, an ATP reading of zero means it is highly unlikely that bacteria are on the surface. But an ATP reading of 100 or greater means there could still be harmful bacteria on the surface.

ATP tests are an approved measure of surface cleanliness by the U.S. Department of Agriculture (USDA) and the International Sanitary Supply Association (ISSA).

Cleaning your entire facility

Keeping your facility safe involves more than just cleaning surfaces. Pathogens can also linger in the air.

Now that you know how to keep your surface as clean as possible, let's discuss an option to disinfectant the air.

The UV FAN by Light Progress sucks in dirty air, disinfects it with UV-C, then runs it through a titanium dioxide (TiO2) nano-structured photocatalyst (TiOx®) filter.

The UV-C inside the fixture energizes the TiOx filter so you never have to replace it. While running, the UV FAN has a proven 99.9% reduction in contaminant load.

The UV-C inside the fixture energizes the TiOx filter so you never have to replace it. While running, the UV FAN has a proven 99.9% reduction in contaminant load.

Our goal is to help you protect your entire building. If you're ready to get started with new cleaning products, UV-C products, or upgraded lighting products, please do not hesitate to contact us.