Plug-and-play vs. ballast-bypass and other linear LED solutions

If you’re looking to convert your linear fluorescent lamps to linear LED lamps, there are now more options and additional risks to consider.

Thanks to new technology and lower prices, it’s easier and more affordable to upgrade to energy-efficient linear LEDs.

Proven, well-known traditional lamp manufacturers have lowered their pricing on LED linear lamps (like T8s). It no longer makes sense to choose products made by riskier, lesser-known lamp manufacturers that use lower pricing to attract customers. Additionally, warranties are important. You want to choose a manufacturer who will stand by its product.

Return on investments (ROIs) in less than a year are becoming more common today, depending on annual burn time, kWh rates, availability of utility rebates for DLC certified products, etc.

Unlike waiting for the next cool technological gadget, or for prices to drop, there is now a cost correlating to your wait to upgrade to more energy efficient lighting – energy and labor savings that you could be enjoying every day.

Ready to shop for linear LED tubes?

If you're a business customer, don't miss out on our business pricing. Apply for an account to receive business pricing here.

Today's T8 linear LED solutions

First, we’re going to break down four options if you’re looking to retrofit from linear fluorescent to linear LED.

1. Plug-and-play or direct fit linear LED (UL type A)

A plug-and-play, or direct fit, linear LED is probably what you're imagining – a simple, one-for-one swap out of the original linear fluorescent lamp. This lamp works directly with the existing fluorescent ballast, so there is no rewiring or ballast change required. But you do want to make sure your ballast is compatible.

Jump ahead to pros and cons.

2. Ballast-bypass, line voltage, or direct wire linear LED (UL type B)

Bypass the ballast linear LEDs – also known as line voltage or direct-wire linear LEDs – work straight off the line voltage flowing directly to the sockets, requiring you to remove the original fluorescent ballast.

Jump ahead to pros and cons.

3. LED lamp and driver (UL type C)

This linear LED solution requires a ballast change, except instead of replacing the ballast with another ballast, you will replace it with an LED driver and your fluorescent lamps are replaced with linear LED lamps.

Jump ahead to pros and cons.

4. Hybrid or dual technology linear LED (UL type A & B)

Hybrid linear LED lamps are able to work both as a plug and play – with the existing ballast – and, once the ballast peters out, you can remove it and have the lamp run off of line voltage.

Jump ahead to pros and cons.

Plug-and-play T8 LED pros and cons (UL type A)

Plug-and-play LED tubes (Type A) pros:

- Simplicity for installer: The lamp snaps into the existing fixture without any wiring modifications, meaning installation can be done by virtually anyone, as long as your existing ballast is compatible.

- Safety: Whenever we can shorten the time someone has to spend dangling from a ladder, things are automatically safer.

- Lowest cost linear LED solution: As a simple one-for-one lamp replacement, the cost of the lamps combined with the minimal labor to install them make them the less expensive option.

- Ballast protection: Fluorescent ballasts are designed to control the flow of current or voltage to the sockets, by regulating the current spikes that commonly occur throughout the day.

Plug-and-play LED tubes (Type A) cons:

- Upfront cost: Even with the recent price reductions for linear LEDs, they are still usually more expensive than existing fluorescent lamps. The positive news, though, is that it is not uncommon to achieve ROIs in under a year based on energy and labor savings.

- Ballast compatibility: While plug-and-play linear LEDs are getting better with ballast compatibility, it's still something you should check. The best way to do this is to take a sample of your common ballasts and make sure they are listed on the manufacturer's approved compatibility list. Our goal is to make lighting easier, so we put together a list of resources where you can check ballast compatibility.

- Continued ballast maintenance: While LED lamps don't put the same stress on a ballast that linear fluorescents do, on-going ballast maintenance is still required.

Ballast-bypass T8 LED tube pros and cons (UL type B)

Ballast-bypass LED tube (Type B) pros:

- No ballast maintenance: Removing the ballast simplifies the number of fixture components that need to be maintained.

- Less energy used through elimination of ballast draw: An extra couple of watts is consumed when you pair an LED lamp with a ballast. Since you're bypassing the ballast, the wattage on the lamp is the wattage consumed. This is called ballast factor.

Ballast-bypass LED tube (Type B) cons:

- Safety risk: The most significant negative to a ballast-bypass linear LED is the risk of electric shock since the sockets carry line voltage. It's a common practice to place a finger on the lamp pins while you are trying to install it, and this becomes a risky endeavor when using single-ended ballast-bypass lamps. Double-ended tubes are not energized until both ends are in the socket, so there is no risk of electric shock. While some LED manufacturers are working on safety designs and updates, we always recommend double-ended LED tubes over single-ended for Type B systems.

- Fixtures must be rewired: It can be argued this is a simple process. Disconnect the ballast from the circuit and wire the sockets to line voltage. There are several video tutorials available to demonstrate this task. Interestingly enough, most of these demos are performed with the fixture being rewired laying on a table. If you've done this before, you understand that doing this over your head while balancing on a ladder (and maybe before your morning coffee) can make things more complicated.

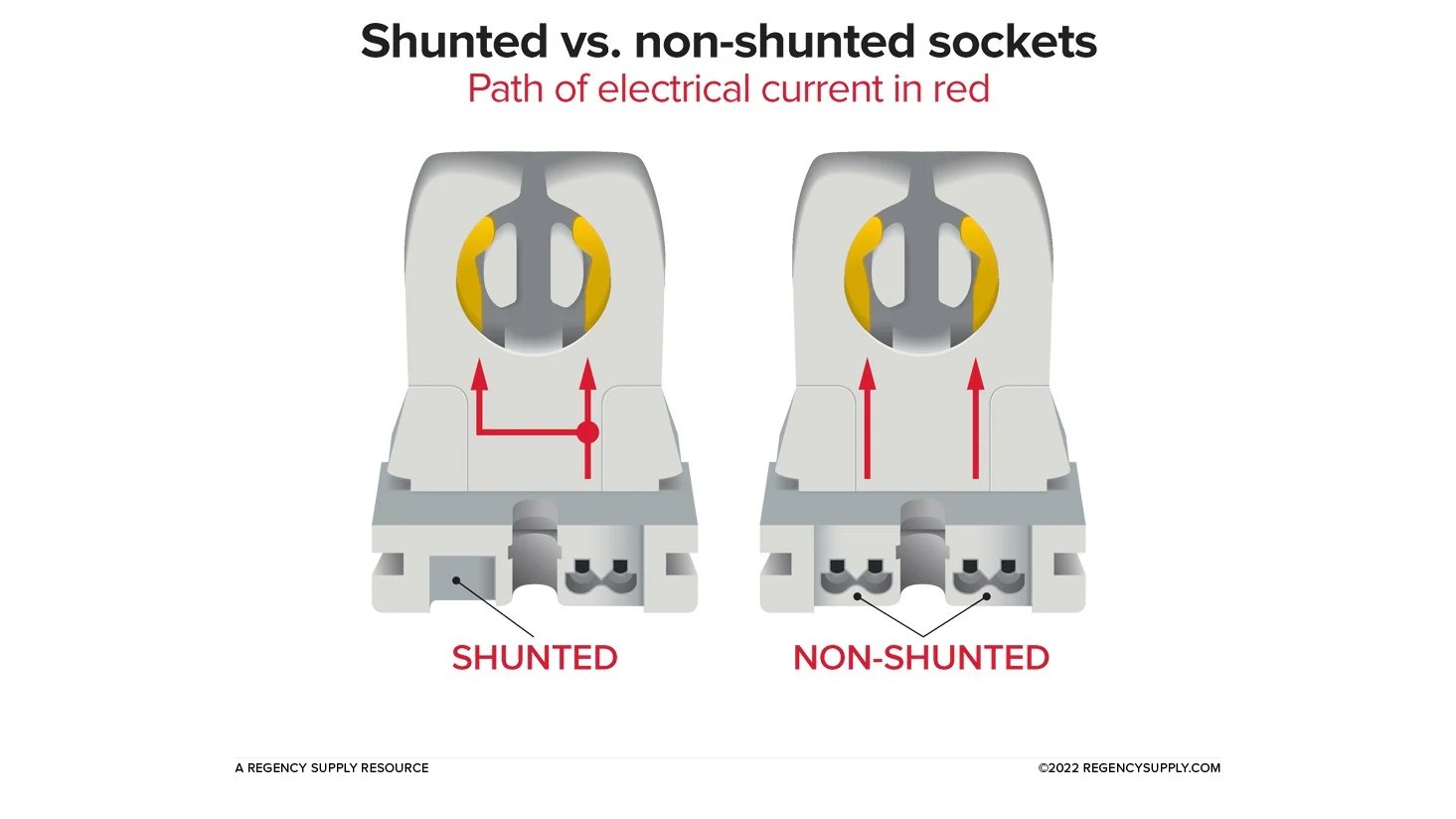

- Exact wiring uncertainty: Unfortunately, there's no industry-standard wiring schematic for ballast-bypass linear LEDs. Different manufacturers have a variety of approaches that the installer must consider. Among the 31 linear lamps tested in a DOE Caliper report, seven different wiring configurations were used. To complicate matters more, there are two common types of lamps – double-ended and single-ended. The type of lamp and the type of socket (shunted or non-shunted) will have an impact on the wiring. This type of variation among commercial products introduces a new layer of complexity, and for safety reasons we recommend using a qualified electrician.

- Fluorescent lamp compatibility or snap-back: We hope that once you retrofit to LED you don't decide to go back to fluorescent, but it's possible that someone could inadvertently install a linear fluorescent lamp in a ballast-bypass fixture. When the LED lamp does need replacing, if you mistakenly try to replace it with a fluorescent, the lamp may not work or could be hazardous.

- Title 24 requirements: In California, there are Title 24 requirements that need to be met when you retrofit existing fixtures by replacing the ballast. Please refer to the current Title 24 requirements for more details.

- Higher initial labor costs: The need to remove the original fluorescent ballast and rewire the line voltage to the sockets requires more labor than plug-and-play solutions that work with the existing fluorescent ballast.

- Socket compatibility: When bypassing the ballast, you may need to change your sockets from the most common shunted sockets to non-shunted sockets. Non-shunted sockets are required if you're using single-ended tubes. This will require a small amount of additional material cost and more labor to replace them all. In addition, some manufacturers may no longer honor the socket warranty if line voltage is direct-wired to their sockets. If you're using double-ended LED tubes, you typically do not need to change your sockets. One of our key partners recently came out with a product that could fix the socket compatibility problem. Sylvania's LEDlescent double-ended ballast-bypass lamps are polarity neutral. That means they work in shunted or non-shunted sockets.

LED T8 lamp and driver pros and cons (UL Type C)

LED lamp and driver (Type C) pros:

- Better energy savings: LED drivers are more energy efficient than today's ballasts. The wattage of the LED lamp is all that is consumed, whereas when used with a fluorescent ballast, the energy consumed increases by about two watts per lamp on average.

- Reduced maintenance: LED drivers are designed to last longer than traditional fluorescent ballasts, thus reducing maintenance costs.

- No ballast compatibility issues: LED drivers properly paired with the right linear LED lamps eliminate any ballast compatibility issues that are often common with plug-and-play LED lamps.

- No snap-back: The term snap-back refers to replacing the energy efficient lamp with the older, less energy efficient technologies (in this case, linear fluorescents). When the LED lamp needs replacing, if you try to replace with a fluorescent, the lamp will not be compatible and not function properly with the LED driver.

LED lamp and driver (Type C) cons:

- Higher initial material costs: Replacing both ballast with an LED driver and new LED linear lamps come with higher material costs when compared to the plug-and-play solutions. This is offset by the higher energy savings and reduced future labor costs.

- Higher initial labor costs: The need to replace the original fluorescent ballast with a new LED driver requires more labor than plug-and-play solutions, which work with the existing fluorescent ballast.

- Title 24 requirements: In California, there are new Title 24 requirements that need to be met when you retrofit existing fixtures by replacing the ballast. Most Type C systems will meet Title 24 requirements, but refer to the current Title 24 requirements for more details.

Hybrid T8 LED pros and cons

Hybrid linear LED pros:

- Greater flexibility: The hybrid lamps were designed to work both with the existing fluorescent ballast and by bypassing it. You can start by using it like a plug-and-play lamp and then, when the ballast fails, you can direct wire it to line voltage.

- Initial simplicity for installer: The lamp snaps into the existing fixture without any wiring modifications meaning installation can be done by virtually anyone.

Hybrid linear LED cons:

- Eventual safety risk: The most significant negative to bypassing the ballast with a linear LED – once the ballast burns out – is the risk of electric shock since the sockets carry line voltage. Most hybrids system use single-ended LED tubes. It's a common practice to place a finger on the lamp pins while you are trying to install it, and this becomes a risky endeavor with ballast-bypass wiring.

- Fixtures must eventually be rewired: It can be argued that this is a simple process. Disconnect the ballast from the circuit and wire the sockets to line voltage. There are several video tutorials available to demonstrate this task. Interestingly enough, most of these demos are performed with the fixture being rewired laying on a table. If you've done this before, you understand that doing this over your head while balancing on a ladder (and maybe before your morning coffee) can make things more complicated.

- DLC listing issues: To be eligible for potential utility rebates, linear LED lamps usually need to be listed on the Design Lights Consortium (DLC) list of certified products. Hybrid lamps are often listed as DLC certified when used with the fluorescent ballast, but are not DLC approved when bypassing the ballast, as it is considered a fixture modification. Some manufacturers may be DLC listed for both.

- Eventual extra labor: Once the original fluorescent ballast dies, the need to remove it and rewire the line voltage to the sockets requires additional labor.

- Fluorescent lamp compatibility or snap-back: We hope that once you retrofit to LED you don't decide to go back to fluorescent, but it's possible that someone could inadvertently install a linear fluorescent lamp in the fixture after you rewire it directly to line voltage. When the LED lamp does need replacing, if you mistakenly try to replace it with a fluorescent, the lamp will not be compatible and not function properly.

Other important things to consider when comparing linear LED solutions

1. Proper socket seating

Though the traditional fluorescent sockets have a plastic exterior, they have metal contacts on each side of the interior of the socket. For a lamp to properly be “seated” in a socket, it needs to snap securely into place to avoid coming loose or moving, and with both of the pins on the LED lamp coming into contact with the metal contacts inside the sockets.

You also want to make sure sockets are not cracked or broken. This could cause socket seating problems. Improper socket seating is the most common cause for fire hazards or melted tubes.

If you want to ensure that you have the proper sockets for your new LED tubes, use this guide. Then, you can purchase the proper sockets (a.k.a. tombstones) here.

2. Emergency ballast compatibility

Many of the traditional emergency ballasts used with fluorescent lamps are not compatible with most of the LED linear solutions on the market today. The most common emergency ballasts that are compatible with LEDs are often much more expensive that the fluorescent versions. This will add to the material cost and labor to the retrofit project. Please make sure your emergency ballast is listed on the manufacturer's compatibility list.

3. Limited dimming options

Though there are currently some good dimmable LED linear options available, the choices are limited and often cost more.

Choosing the right linear LED

The first part of your linear LED decision should involve choosing a reputable manufacturer. You want to work with someone that has put their product through proper testing and will ultimately stand by it. In our experience, some of the best linear LEDs on the market include Sylvania’s SubstiTUBE products and Philips InstantFit. We also carry products from MaxLite and TCP.

The second part of your decision is which linear LED solution is best for your application. The most common decision is ballast-bypass vs. plug-and-play. For some, the ease of installation on plug-and-play products is attractive, but for others, the simpler long-term maintenance of a direct-wire LED is valuable. Both are viable options that will save your property time and money, but we strongly recommend either plug-and-play or a double-ended ballast-bypass.

Here's why:

Your safety is extremely important.

If you choose ballast-bypass LED tubes, look for a direct-wire lamp that comes with a valid "modification" sticker to affix to the fixture and preserve its UL listing.

Finally, the LED lamp and driver option offers great long-term maintenance savings and light output, but the higher cost will extend your payback.

As you consider the variables that go into a lighting retrofit decision, remember to evaluate your priorities for the project and keep safety first.

If you're a business customer, don't miss out on business pricing in our online store. Apply for an account to receive business pricing here.

This article has been updated to include new linear LED solutions and current recommendations. It was originally published in September 2015.