Does bypassing the ballast with an LED tube void the UL rating on a fixture?

Unlike fluorescents, some linear LEDs do not need a ballast to power up and produce light. So, a lot of our customers have been asking us about the safety of just bypassing the ballast and direct-wiring their LED tubes.

Several years ago, we saw a lot of problems with this. People were using the wrong sockets. Fires were starting because of mistakes during install. Fluorescent tubes were accidentally post-installed instead of LED tubes, and they were failing immediately when they came into contact with the line voltage running to the sockets.

Back then, we were adamant with our warnings against ballast-bypass linear LED solutions. There were just too many safety hazards for us to recommend this, and the technology wasn't quite there.

But recently, we've seen some notable advancements

Before we answer one of the main questions we get about this solution, let's walk through the basics of direct wire (or ballast-bypass) linear LED installs.

What is a ballast-bypass LED tube? How does it work?

Line voltage or direct-wire linear LEDs – also known as ballast-bypass LEDs – work straight off the line voltage flowing directly to the sockets, requiring you to remove the original fluorescent ballast. They are more efficient than plug-and-play LED tubes, as they don't lose energy to ballast draw.

What are the pros and cons of direct wire or ballast-bypass (UL type B) LEDs?

The below is borrowed from our post "Plug-and-play vs. ballast-bypass and other linear LED solutions." Read more here.

Direct wire T8 LED tube (UL type B) pros:

- No ballast maintenance Removing the ballast simplifies the number of fixture components that need to be maintained.

- Less energy used

through elimination of ballast draw An extra couple of watts is consumed when you pair an LED lamp with a ballast. Since you're bypassing the ballast, the wattage on the lamp is the wattage consumed. This is called ballast factor.

Direct wire LED tube (UL type B) cons:

- Safety risk The most significant negative to a ballast-bypass linear LED is the risk of electric shock since the sockets carry line voltage. It's a common practice to place a finger on the lamp pins while you are trying to install it, and this becomes a risky endeavor when using single-ended

ballast-bypass lamps . Double-ended tubes are not energized until both ends are in the socket, making it a safer option. Some LED manufacturers have included safety designs to address the risk of electric shock, but we always recommend double-ended LED tubes for Type B systems. - Fixtures must be rewired It can be argued that this is a simple process. Disconnect the ballast from the circuit and wire the sockets to line voltage. There are several video tutorials available to demonstrate this task. Interestingly enough, most of these demos are performed with the fixture being rewired laying on a table. If you've done this before, you understand that doing this over your head while balancing on a ladder (and maybe before your morning coffee) can make things more complicated.

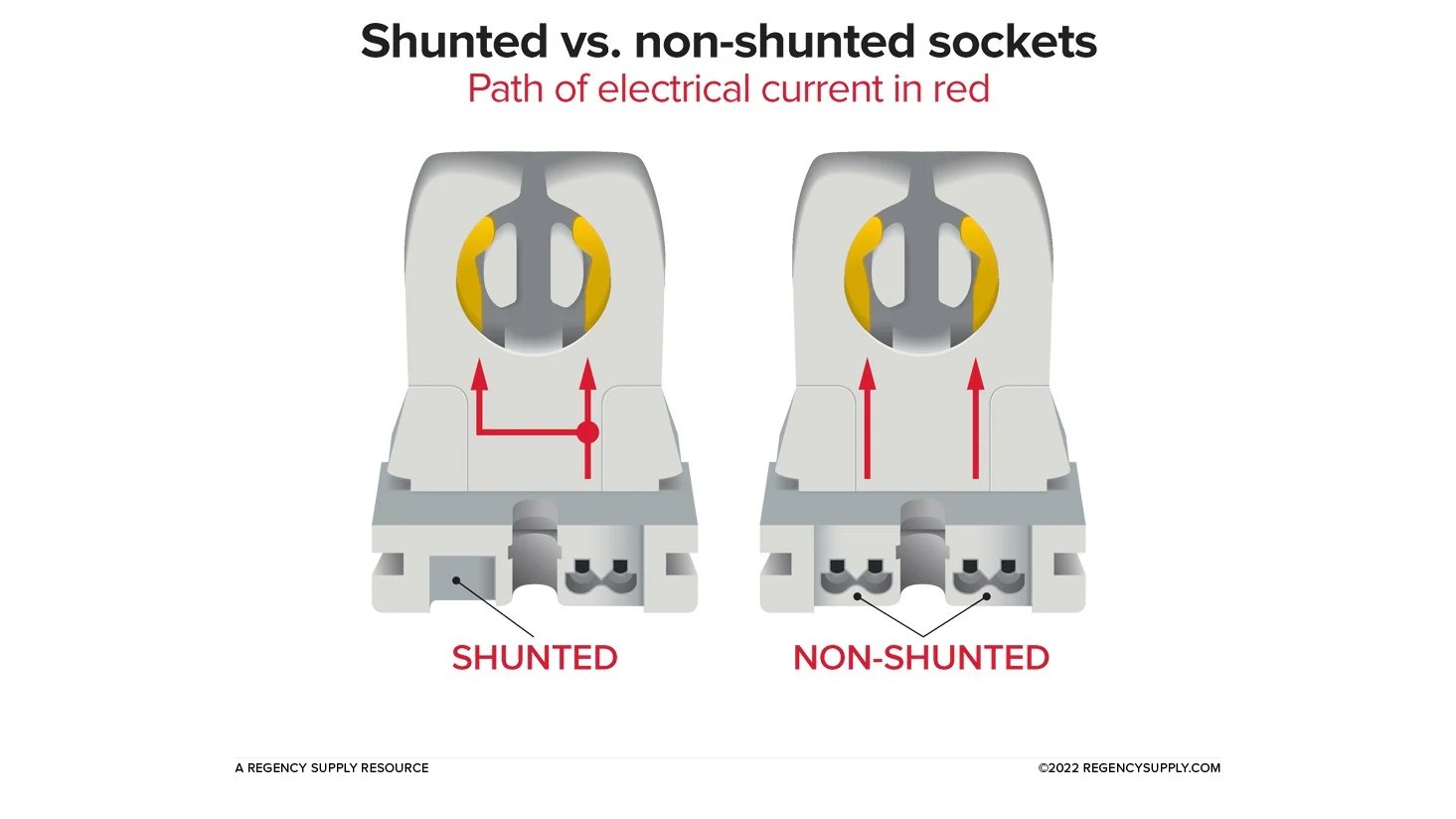

- Exact wiring uncertainty Unfortunately, there's no industry-standard wiring schematic for ballast-bypass linear LEDs. Different manufacturers have a variety of approaches that the installer must consider. Among the 31 linear lamps tested in a DOE Caliper report, seven different wiring configurations were used. To complicate matters more, there are two common types of lamps – double-ended and single-ended. The type of lamp and the type of socket (shunted or non-shunted) will have an impact on the wiring. This type of variation among commercial products introduces a new layer of complexity, and for safety reasons we recommend using a qualified electrician.

- Fluorescent lamp compatibility/snap-back We hope that once you retrofit

to LED you don't decide to go back to fluorescent, but it's possible that someone could inadvertently install a linear fluorescent lamp in a ballast-bypass fixture. When the LED lamp does need replacing, if you mistakenly try to replace it with a fluorescent, the lamp may not work or could be hazardous. - Title 24 requirementsIn California, there are Title 24 requirements that need to be

met when you retrofit existing fixtures by replacing the ballast. Please refer to the current Title 24 requirements for more details. - Higher initial labor costs The need to remove the original fluorescent ballast and rewire the line voltage to the sockets requires more labor than plug-and-play solutions that work with the existing fluorescent ballast.

- Socket compatibility When bypassing the ballast, you may need to change your sockets from the most common shunted sockets to non-shunted sockets. Non-shunted sockets are required if you're using single-ended tubes. This will require a small amount of additional material cost and more labor to replace them all. In addition, some manufacturers may no longer honor the socket warranty if line voltage is direct-wired to their sockets. If you're using double-ended LED tubes, you typically do not need to change your sockets. One of our key partners recently came out with a product that could fix the socket compatibility problem. Sylvania's LEDlescent double-ended ballast-bypass lamps are polarity neutral. That means they work in shunted or non-shunted sockets.

What is UL rating and is it required for your fixture?

If a product comes with a UL mark, it signifies that it has passed Underwriter Laboratories’ (UL’s) safety requirements for use by consumers and in places of business.

In an electrical product, like a light fixture, UL tests to make sure it won’t end up malfunctioning and causing a fire, or some other safety hazard.

If a product is UL (or ETL) listed, or certified, it is deemed safe for the public. That’s precisely why either UL or ETL listing is almost always required by commercial building code.

Does installing a direct wire/line voltage LED tube void the UL rating of your fixture?

The short answer is no, but there's an important caveat. In order to maintain UL listing on your original fixture, you must place a modification sticker on the inside of the fixture, which lets electrical inspectors know that the fixture has been altered to bypass the ballast and directly transfer voltage to its sockets.

The following additional clarification was given by one of our manufacturer partners, Maxlite, at a seminar regarding this topic:

Basically, the UL certification is now transferred to the LED tube/retrofit kit, which is covered under UL standard 1598c. Installers should follow all instructions and the fixture must be clearly labeled to warn users against re-installation of fluorescent lamps.

Most reputable LED tube manufacturers these days include relamping stickers with the purchase of their products, making it easier for installation crews to properly modify fixtures.