UVC fixtures for HVAC systems [Pros and cons]

The COVID-19 pandemic caused many industries to rethink how to protect their employees, customers, and tenants.

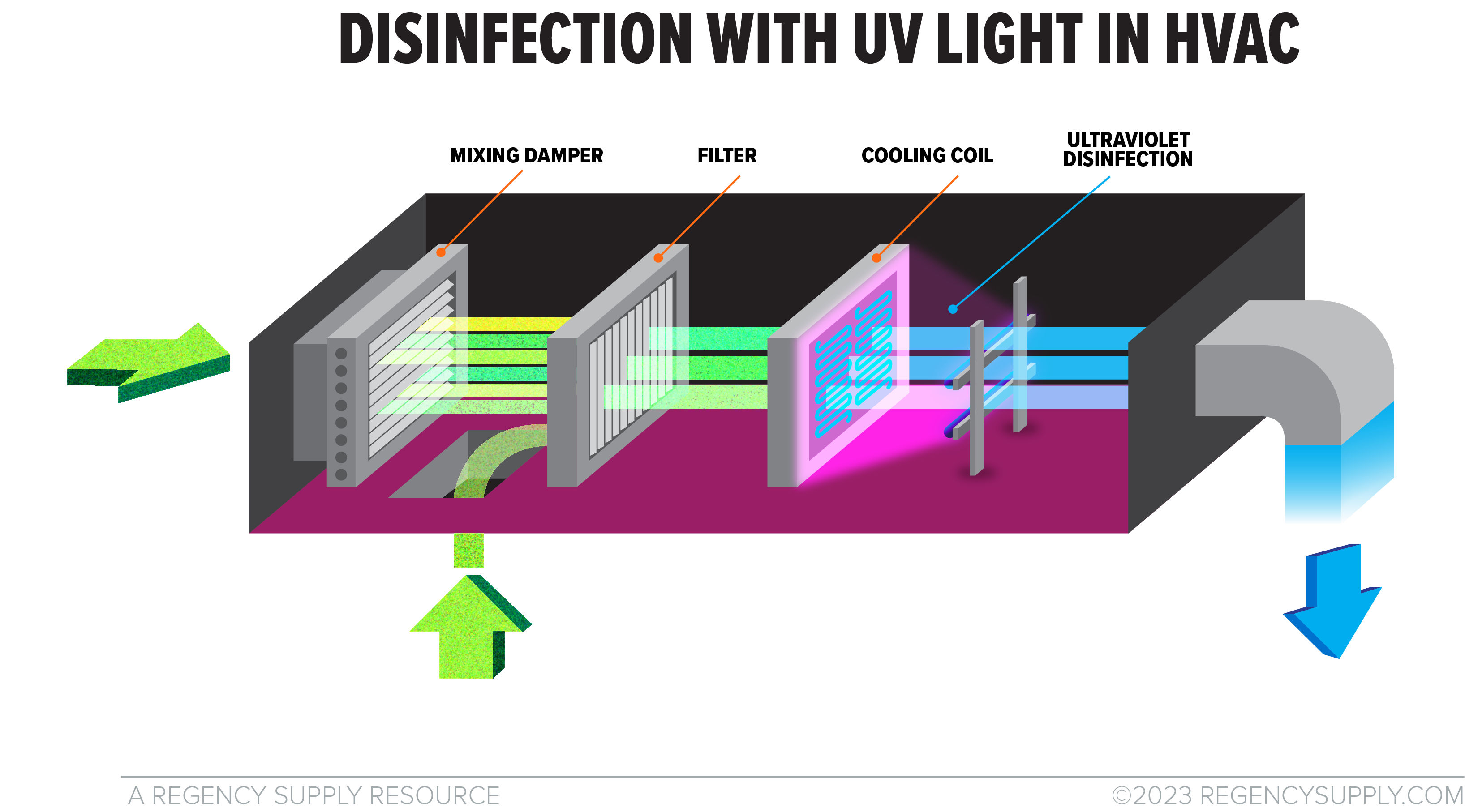

One of the biggest takeaways: clean air should be a priority. UVC fixtures for HVAC systems are an effective tool to eliminate pathogens in facilities and improve indoor air quality (IAQ).

Because HVAC systems in hotels, offices, hospitals, schools, restaurants, and stores are all unique, each application is also unique. When you work with a trusted partner, you can configure an option that's right for your system and delivers the best results.

Pros and cons of UVC fixtures for HVAC equipment

The benefits of using germicidal UV are two-pronged: clean, healthier air in your building and a cleaner, healthier HVAC system (which means less maintenance, odors, and an overall longer-lasting system).

However, a report from the Illuminating Engineering Society mentioned one flaw in using germicidal UV HVAC fixtures. While the products disinfect air, they do little to stop person-to-person transmission.

Here's an overall look at the pros and cons of using UVC fixtures on HVAC equipment.

Pros for using UVC fixtures in HVAC systems:

1. Energy savings. UVC fixtures not only clean your system, they improve the heat exchange efficiency. That means your energy costs are going down.

2. Reduced maintenance. UVC acts as a source of constant maintenance for your HVAC system. Instead of having to constantly pressure wash or clean equipment, UVC rays constantly clean and disinfect, leading to less build-up.

3. No harsh chemicals. You can stop using those bleach tablets in your drain pans. UVC will replace or reduce the use of harsh chemicals. Plus, you can enter a room immediately after the products are turned off. No need to wait for harsh chemicals to dissipate.

4. Improved indoor air quality. UVC can help disinfect at the source of germs, which is typically coils or drain pans. When installed in-duct, fixtures can also greatly reduce the threat of pathogens entering the building through the HVAC system.

Cons for using germicidal UV for HVAC:

1. Safety requirements. Germicidal UV for HVAC applications is not dangerous when it is used correctly, but maintenance workers need to use extra caution. The proper safety equipment should be worn at all times. We advise strictly following manufacturer guidelines.

2. Access to equipment. Access to HVAC equipment may be limited if your germicidal UV equipment is constantly running. Also, access to the germicidal UV equipment itself may be limited based on where it is installed.

3. Specifications required. Every air handling unit is different and requires different specifications before UVC products can be installed. Working with the right partner can easily turn this con into a pro.

UVC applications for HVAC equipment

1. Coil-mounted UVC fixtures

Coil-mounted or coil-focused UVC fixtures are installed at the coils and drain pans of the HVAC system.

These are often used on larger systems, where there is more room to mount a fixture or a series of fixtures.

Watch below: we installed coil-mounted UVC fixtures on the HVAC system at our headquarters.

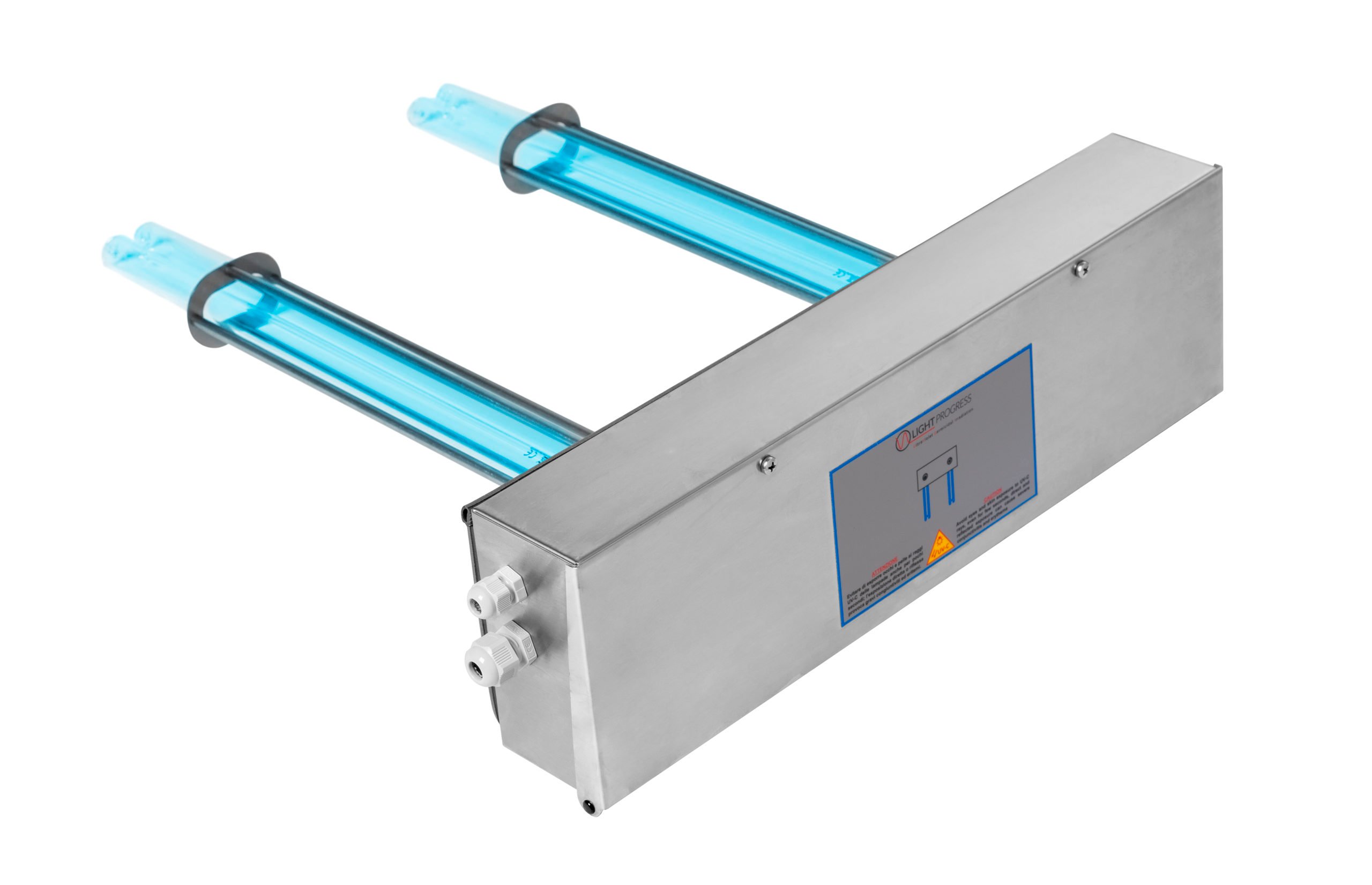

Light Progress HVAC coil-mounted fixtures

Light Progress offers several options to disinfect industrial HVAC systems.

|

|

|

| UV-Stylo-E by Light Progress |

UV-Stylo-F by Light Progress |

UV-Stylo-X by Light Progress |

The UV Stylo comes in three different shapes and configurations to fit inside multiple air handling units.

The Stylo is laid in the bottom of a unit or attached to the HVAC cabinet with either mounts or magnet. If laid in the bottom of the unit, the housing around the UVC lamp protects it from water damage.

The Stylo prevents bacteria from growing that can be harmful to the system. Each version has its own benefits.

The UV-STYLO-E has been designed to sanitize water directly within basins, sinks, washing systems, and more.

The UV-SYLO-F is applied inside fan coils or in narrow spaces inside small ductless systems. It helps with continuous disinfection and cleaning of the fan coil.

The UV-STYLO-X can be applied inside air conditioning systems and fits in narrow spaces.

There are several factors to consider before specifying and installing the Stylo by Light Progress.

- Get the dimensions of the unit so you can find the product that works best.

- Consider adding a door safety switch. This is a switch that's triggered if the door or cabinet is opened. The UVC lamp will automatically power off and there is no risk of UVC exposure.

- Another safety option is called a sight glass. A sight glass allows you to look inside the unit to check on the lamp without having to open the cabinet. This is also a way to let maintenance workers know that there is UVC inside the unit and to take necessary safety measures.

- You may need to shield material inside the unit from UVC rays. UVC can cause some deterioration of materials over time, so it's better to take precautions.

PURO UVC fixture for HVAC

PURO™ Lighting is taking a new approach to germicidal UV HVAC solutions. Instead of mounting a system directly to coils, the company suggests using its Helo F1 fixture aimed at coils.

|

| PURO™ Lighting Helo F1 |

The fixture should be mounted six feet away. The Helo F1 will emit broad-spectrum UV to the HVAC coils in one to two hour cycles.

Instead of running constantly, the Helo F1 runs for two hours or less. A single unit uses 45 watts of energy. That can save thousands of dollars a year for large industrial buildings.

If the Helo F1 is running when someone walks into the room, it will automatically shut off. The occupancy sensor detects motion. This could help create a safer work environment for maintenance staff.

Regardless of your approach, coil-focused solutions can be highly configurable to meet the needs of your industrial system. Contact us for a custom solution.

2. In-duct UVC fixtures

In-duct UVC fixtures are an option when air handling units are smaller and there isn't enough room to set up a coil-mounted system. They're also effective at disinfecting air as it passes through the system and before it reaches rooms, providing an extra layer of protection against pathogens.

Watch below: we installed in-duct UVC fixtures at our headquarters.

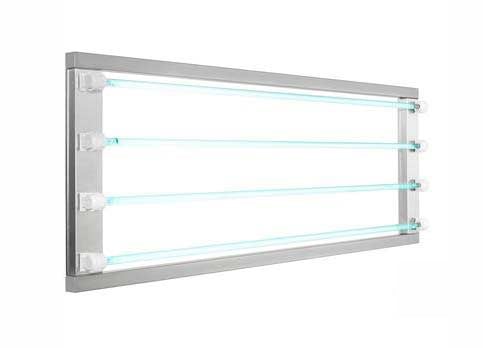

Light Progress HVAC duct-mounted fixtures

Light Progress offers three options for duct-mounted fixtures.

|

| UV-DUCT-FL-NX by Light Progress |

The UV-DUCT-FL-NX is typically applied inside ducts or in the final section of the Air Handling Unit. It prevents pathogens from settling inside HVAC systems and lowers the distribution of bacteria, viruses, and mold inside buildings.

|

| UV-DUCT-SQ by Light Progress |

The UV-DUCT-SQ is a versatile unit with a shape that can easily adapt to different applications. It can be mounted by itself or combined with other modules.

The fixture creates a "UVC section," purifying air as it passes by the lamp, lowering the spread of pathogens inside facilities.

|

| UV-RACK by Light Progress |

The UV-RACK is a larger unit that can be installed inside ducts or in the final section of the air handling unit. This is an option for larger units.

In-duct UVC fixtures are a versatile and flexible option to improve indoor air quality (IAQ) in your facility. You can easily replace lamps from outside of the duct work. As long as the light on the outside of the unit is green, the UVC lamps are at work disinfecting air in the building.

UVC HVAC solutions

Every UVC solution is unique based on the industrial HVAC system in each commercial building.

To find the best solution for you, contact us to speak with one of our lighting specialists.

Using UVC on your HVAC system is a great place to start with disinfection, but it should not replace other cleaning and protective measures.

Shop PPE and other sanitizing solutions

UVC products can also be used together to make sure you have the best line of defense against bacteria and viruses in your building.