Types of electrical wire insulation and protective coverings

Important to know the difference when you're installing wire in new building

Building wire is a critical part of any construction project. The right wiring ensures that the lighting, devices, and appliances all operate, but the right kind of building wire is also important for meeting code and building safety.

Wire comes with its own set of acronyms and part numbers, so we're walking through the practical differences between examples like THHN and THWN-2 and XHHW-2 so you know what your project needs and what type of wire you're getting. Each type of wire has a purpose, so we'll also compare common applications and uses for the different types of wire insulation.

But first, let's cover the different types of protective coverings on wire. Then, we'll dig deeper into the types of wire insulation.

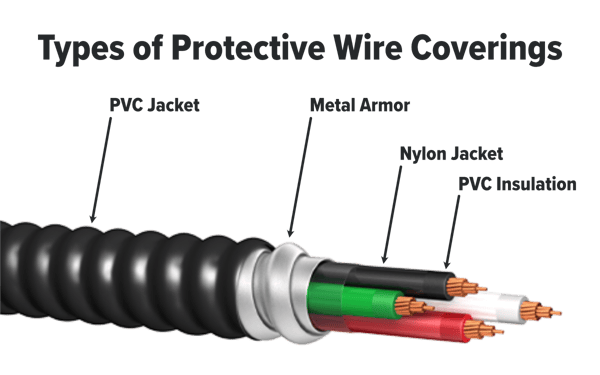

Types of protective coverings for electrical wires

There are three basic types of protective coverings for electrical wires: armor, jacket, and insulation. Each one serves a different purpose and offers a different level of protection.

Armor

Armor is typically made from galvanized steel or aluminum interlocked armor (AIA). It's used for mechanical protections in commercial applications. Essentially, armor is like running wire with built-in conduit protection.

Jacket

Jacket is an outer covering that's used to protect against the environment. A jacket is typically non-metallic. Nylon and PVC are examples of jacket protective covering. This helps protect the insulation around a wire when the wire is being pulled through conduit. It can also make pulling the wire through conduit easier by reducing friction.

Insulation

Insulation is a covering material with a high resistance to electrical flow. PVC and XLPE are examples of insulation. This material keeps the electrical current flowing through the wire contained in the wire.

Types of insulation for electrical wire

Because insulation has the highest resistance to electrical flow, some form of insulation is used with all non-bare wiring — which is the majority of all applications in commercial projects. As we mentioned above, PVC and XLPE are the most common types of insulation.

PVC is a thermoplastic product. THHN/THWN-2 and NM-B are types of thermoplastics. PVC can be heated, shaped, and cooled to a desire state. On the other hand, it can also break down or leak in demanding environments. PVC is also thinner than XLPE.

XLPE is a thermoset product, which makes it more resistant to chemicals, ozone, and abrasions. Thermosets are typically more flexible than thermoplastics and also far less toxic in the event of fire.

Besides the differences between a thermoset and thermoplastic, what are the practical differences between the alphabet soup of THHN/THWN/THWN-2 (PVC) and XHWW/XHHW-2 (XLPE)? Keep reading below for what you need to know.

XHHW-2 vs. THHN/THWN: What's the difference?

THHN/THWN/THWN-2 and XHHW/XHHW-2 may be a lot of letters to understand, but the letters are important to the function of the wire. Like many lighting part numbers, they can tell you the properties of what you're ordering.

To help visualize the differences, see the chart below:

ACRONYMS EXPLAINED:

| THHN/THWN/THWN-2: | XHHW/XHHW-2: | |

| Type: | T = Thermoplastic (PVC) | X = Cross-Linked Polyethylene (XLPE) |

| Jacket: | N = Nylon Jacket |

Thicker, more protective insulation, so a jacket is not required. |

| Conditions: | HH = High heat resistant W = Water resistant -2 = Temperature Rated 90°C in dry and 75°C in wet conditions; Approved for 600V |

HH = High heat resistant W = Water resistant -2 = Temperature Rated 90°C Wet/Dry |

| Qualities: | Less flexible Less resistant to abrasions |

More flexible More resistant to chemicals & abrasions |

| Wire Material: | Copper or aluminum | Copper or aluminum |

| Applications: | Residential, commercial, and general applications | High voltage, critical (e.g. healthcare), extreme temperatures (e.g. extreme winter weather, high thermal loads, etc.), chemical exposure |

Flexibility:Surprisingly, even though XHHW has a thicker and more protective jacket, it is also more flexible than THHN wire. This is due to the XLPE insulation of the XHHW allowing the cable to bend and flex more easily than the PVC insulation of the THHN – making XHHW much easier to work with during the installation process.

In addition to the chart, there are a few differences to note.

THHN wire comes with a dual rating: THHN/THWN. TH'W'N means the wire is water-rated and is appropriate for both wet and dry conditions.

XHHW wire is generally a sturdier wire. XHHW-2 is the 'next generation' version of the XHHW wire. The biggest difference is that XHHW-2 is UL listed for 90°C for wet and dry locations, making it more versatile in demanding environments.

Finding the right electrical wire

As always, the decision between using THHN or XHHW comes down to meeting code and weighing performance versus budget. Our customers often express that the more popular and less expensive THHN/THWN wire is perfectly suitable for what they need. On the other hand, XHHW has the additional features that provide increased protection and extended longevity.

When you're ready for your next building project, contact us to help you with project. Our team of experts know electrical wire inside and out and can offer the best solution to fit your needs, while also keeping your budget in mind.