Pros and Cons of Copper and Aluminum Wire

lkjlkj

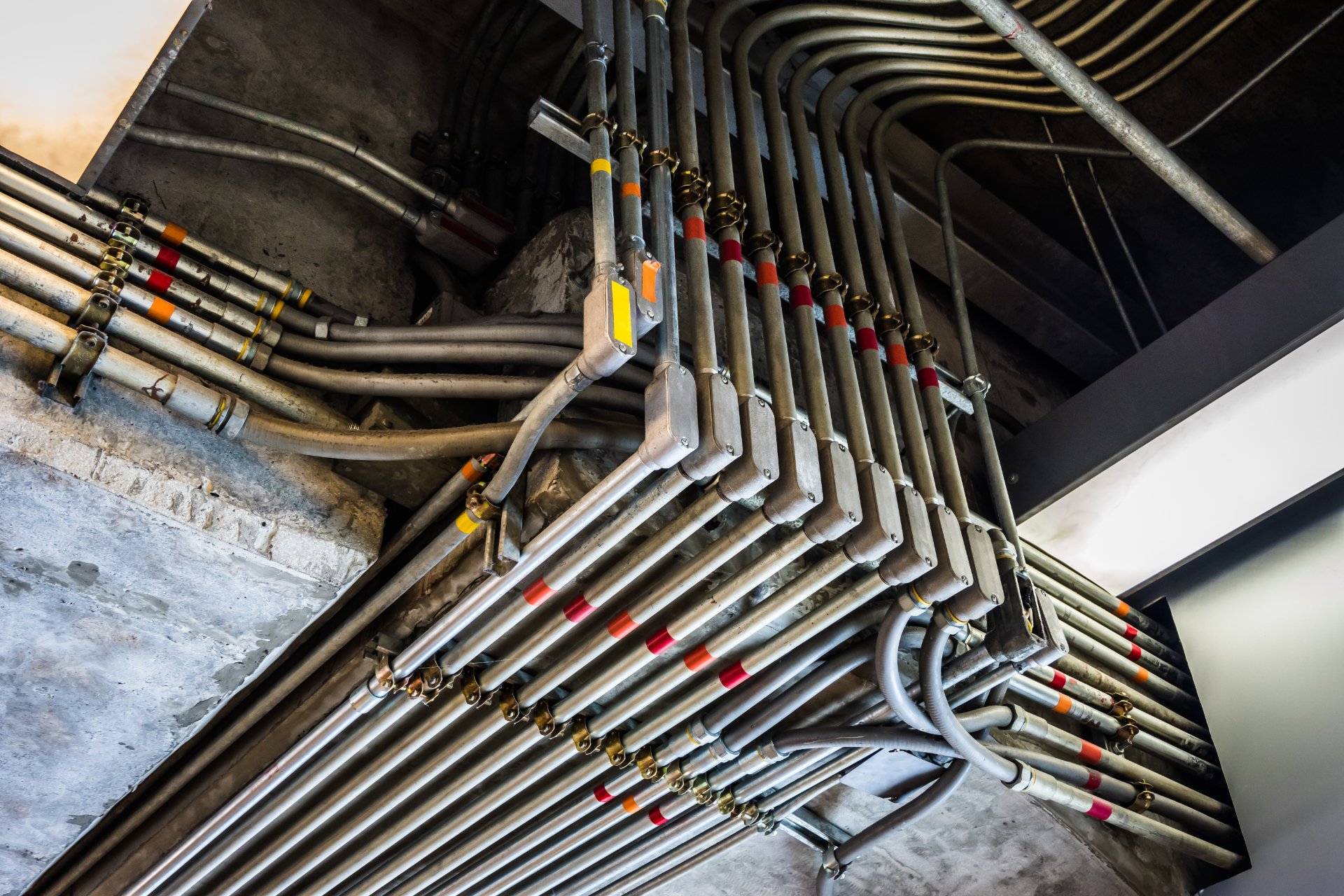

Cooper and aluminum are the most common types of metal conductors used in electrical wires. They're efficient, easy to use, and affordable. But each type has its advantages and disadvantages — and understanding the best applications for each will help you avoid potential problems down the road.

For example, the cost of copper is often higher than aluminum. If you based your final choice on cost alone, the choice is obvious: aluminum. But what if you also need a versatile option that can withstand the test of time? Copper is most likely your first choice now. Let's dive into the pros and cons of each type.

Read more: Different types of wire

When to use copper wire

Traditionally, copper wire is preferred over aluminum wiring because of its strength and durability over time. Overall, copper conducts electricity better than aluminum, is less likely to corrode, and doesn't expand and contract as much as aluminum.

Copper is also extremely flexible, which is a priority when wiring needs to handle a large loads of electricity at one time. Let's take a look at some of the pros and cons.

Pros of copper wiring

There are many advantages to copper wiring:

- Conductivity. Copper wire is highly conductive and transfers electricity well.

- Tensile strength. Copper wire does not expand and contract as much as other wiring. Its tensile strength allows it to handle wear and tear over time, about 40 percent better than aluminum wiring.

- Higher ampacity. Ampacity is the maximum current a conductor can carry without exceeding its temperature rating. Copper can carry a high current without overheating.

- Versatility. Copper can be formed into very fine wire and can easily be mounted by pulling it through ports and feeders.

- Easy to recycle. Recycling copper wire is not only good for the environment, it's also good to keep the supply moving.

- Better known longevity. Copper does not require much maintenance after its installed.

Cons of copper wire

While copper wire may seem like a superior choice, there are several disadvantages:

- Price. Copper is much more expensive than aluminum, which will increase the overall cost of a project.

- Weight. Copper is heavier than aluminum, so in certain applications, copper can be more complex to install than its lighter weight counterpart, aluminum.

- Theft. Thieves often target copper wire over aluminum wire because it's more expensive than other types of wiring.

- Support. Copper wire requires more support over long distances to keep it in place. On top of paying extra costs to supply copper wire for long distances, you could also end up paying more for installation support.

When to use aluminum wire

Aluminum wiring became popular in the 1960s and 1970s when copper prices soared. Aluminum wiring for commercial buildings generally saves a lot of money, and when properly installed, is extremely safe. But there are some drawbacks. Let's explore the pros and cons.

Pros of aluminum wire

- Lighter weight. Aluminum is a lightweight material that's very flexible. Installs are often faster since wire pulls are much quicker in long runs.

- Less expensive per pound. Aluminum is considerably less expensive than copper, which makes it more desirable to use in large projects where runs span long distances.

Cons of aluminum wire

- Less longevity. Prone to cracking and failure when subject to vibration. Aluminum is also more subject to corrosion than copper, meaning its useful life can be shorter as it becomes brittle and subject to breakage.

- Difficult to solder. Aluminum is difficult to solder, limiting its flexibility. Oxidation on aluminum often inhibits soldering.

- Larger size. Because aluminum conductors are larger than copper conductors, larger raceways are required (and additional costs).

- Potential dangers when use incorrectly. When aluminum is properly installed, it is safe. When it is installed incorrectly, there is a potential risks for fire because expansion and contraction cycles have a larger impact on aluminum and can loosen connections. Normal inspections should be performed.

- Terminal points. Aluminum requires an anti-oxidation compound at each terminal point because it is susceptible to oxidation. Oxidation occurs when it comes into contact with moisture and dissimilar metals.

Can both aluminum and copper wire be used?

There are a few instances where you may consider using both aluminum and copper wire. For instance, if aluminum wire already exists but you want to expand with copper wire, there are specific connectors marked Cu-Al to make the connection.

However, mixing between wires can be tricky. Aluminum wire requires specifically rated devices for outlets and switches. Using other devices poses a risk.

Choosing between copper and aluminum wire

Each project is different, and it may not be cut and dry whether to use aluminum over copper or copper over aluminum. We encourage careful consideration when weighing your options.

If you're still examining factors, contact us to help you with your project. Our team of experts know electrical wire inside and out, and can offer the best solution to fit your needs, while also keeping your budget in mind.